After much anticipation, we finally receive a pair of bought Ag-coated mirrors from Newport. Within seconds we were able to tell these guys were much better ("order(s) of magnitude better", says Keita) than any other TMS mirrors used for LIGO.

One of them only had a few "spots" which could be seen from the front with light behind it. And this one had no "cloudiness" observed with many other mirrors. The second mirror had minor cloudiness (but they "cleared up"?), and this one had virtually NO holes in it.

Both were cleaned and we took out to EX TMS Lab. We removed the Alignment mirror serving as an F1 Mirror and upon installing the new Newport mirror, Keita noticed that these mirrors are thinner (!). They are probably a couple millimeters thinner than the original mirrors. We were able to accomodate the mirrors by screwing the pitch/yaw actuators out a little more. New mirror was installed and this is where we stopped for the day.

I would have liked to install the tons of pictures we took, but RESOURCE SPACE HAS BEEN DOWN!!! (all afternoon and evening) :(

Attached to this entry are a sample of photos.

"Orders of magnitude" is a serious comment.

You can see many tiny spot defects on the new mirror because it's without other terrible things.

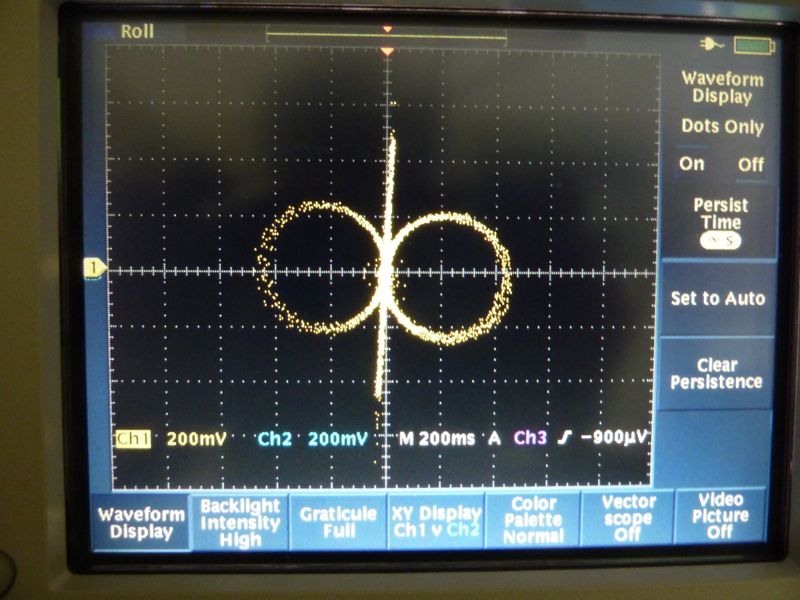

As far as the number of coating holes per area is concerned, the new one (Newport) is roughly three orders of magnitude better than the best Edmund mirror (picture) and the alignment mirror (picture).

No systemic scratch (VS something like this bad Edmund).

A very faint bluish color was found in the new mirror but it's much much better than Edmunds.