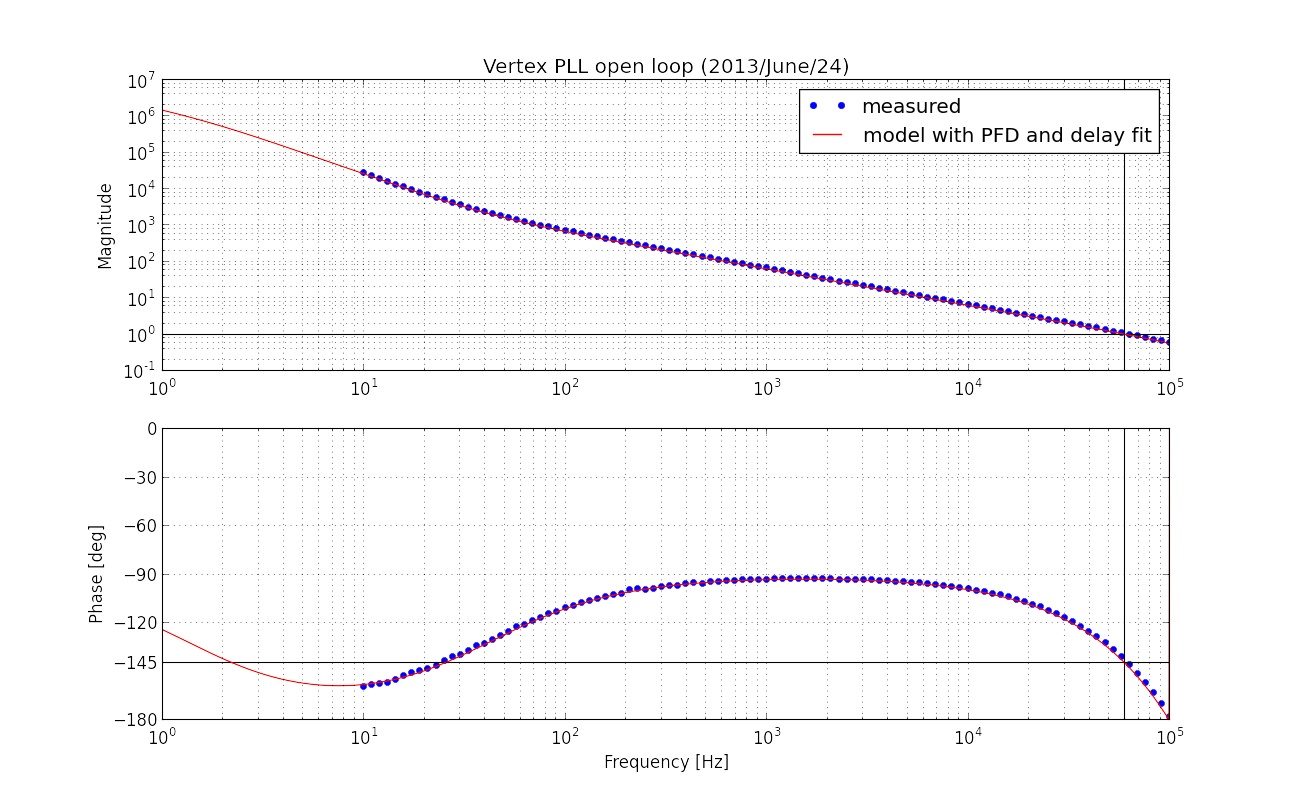

(Chris, Kiwamu, Stefan)

We roughly calibrated the IR transmitted light (still ASC Quad sum, since Sheila wasn't quite able to finish due to a short earthquake).

Method:

- We sit on the side of the fringe (peak/2) of the IR cavity fringe, which has a pole frequency of 82Hz, i.e. power is proportional to P0/( 1+( f/82Hz )^2 ) .

- This gives a slope of dP/df = Po/(2*82Hz), i.e. the DC calibration (with P0=250cts) is 0.656Hz/ct (at DC)

- The cavity pole is now complex (since the two freq-mod side bands see different transfer function), but we were too lazy to do this math right, and just stuck in a real zero at 82Hz to compensate the cavity pole. This is good within a factor of 2 above the cavity pole.

The attached plot shows

- Green: Transmitted IR at peak/2, calibrated in Hz/rtHz

- Dashed-Green: RMS of previous one.

- Blue: MC_F, calibrated in Hz. above the x-over (~100Hz) this measures the laser frequency drive

- Mustard: Ey PLL noise, calibrated in Hz (free running Laser noise)

- Gold: EY PDH control signal (actually wong - should be ~10 times higher, due to the changed PDH control scheme - see previous elog for correct calibration)

Conclusion: we supress real motion down to ~40Hz, above that we are imprinting ALS sensing noise (probably from the corner setup) onto the IR light. The obvious strategy to lower the 34Hz RMS noise is to lower the UGH (turn the AO path off) and add some significant boost filters at low frequency. Our initial attempt for doing this ran into DAC saturation issues on MC2.